项目(Item) | 说明(Specifications) |

步距角(Step Angle) | 1.8。 |

步距角精度(Step Angle Accuracy) | ±5% (整步,空载) |

径向间隙( Radial Play) | 0.02mm@450 g |

轴向间隙( Axial Play) | 0.08mm@450 g |

最大径向负载(Max. radial force) | 75N 距法兰20mm (20mm from the flange) |

最大轴向负载(Max. axial force) | 15N |

介电强度(Dielectric Strength) | 600VAC / 1S |

绝缘电阻(Insulation Resistance) | 100MΩ ,500VDC |

环境温度(Ambient Temperature) | -20。C~+50。C |

绝缘等级(Insulation Class) | Class B |

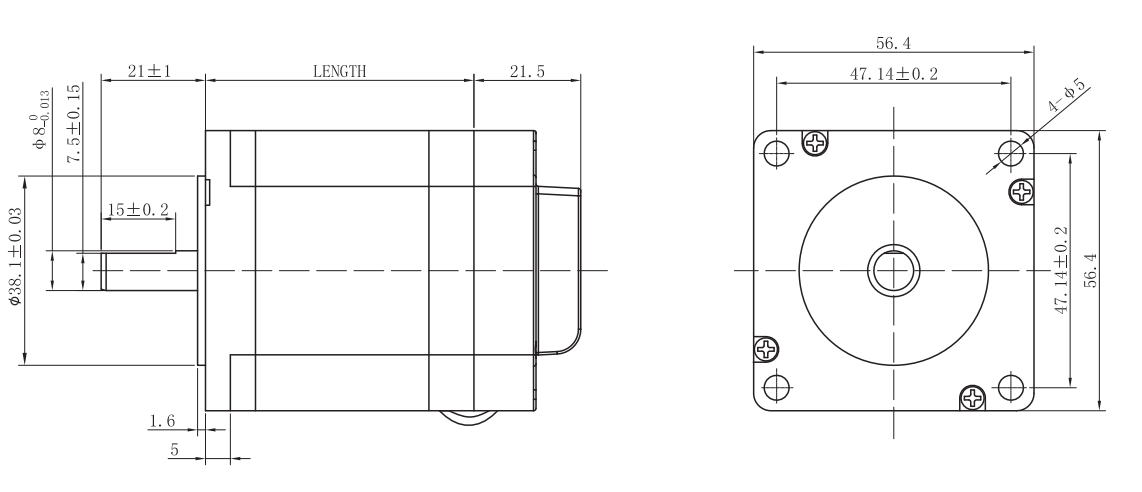

型号(Model No.) | Current /Phase 每相 电流 | Resistance /Phase 每相 电阻 | Inductance /Phase 每相 电感 | Holding Torque 保持 转矩 | Detent Torque 定位 转矩 | # of Leads 引出线数 | Rotor Inertia 转动惯量 | Weight 重量 | Length 机身 长度 |

Single shaft (单出轴) | A | Ω | mH | N.m | N.m | # | g-cm2 | kg | mm |

IO57-10 | 2.8 | 0.9 | 2.5 | 1.26 | 0.04 | 4 | 300 | 0.9 | 54±1 |

IO57-22 | 5.6 | 0.4 | 1.8 | 2.2 | 0.07 | 4 | 500 | 1.5 | 80±1 |

说明(Specifications) | 最小值(Min.) | 典型值(Typ.) | 最大值(Max.) | 单位(Unit) |

输入电压(直流)/ Input voltage (DC) | 20 | 36 | 50 | Vdc |

输出电流(峰值)/ Output current (peak) | 1.5 | - | 5.6 | A |

步进脉冲频率/ Step pulse frequency | 0 | - | 200 | KHz |

脉冲电压/ Pulse voltage | - | 5 | - | Vdc |

控制信号输入电流/ Control signal input current | 7 | 10 | 16 | mA |

绝缘电阻/ Insulation resistance | 100 | - | - | MΩ |

引脚说明 (Pin description) | 功能(Function) |

+Vdc | 电源电压:0~50 Vdc,包括电压波动和EMF电压。 Power supply, 20~50 Vdc, Including voltage fluctuation and EMF voltage. |

GND | 接地(Power Ground) |

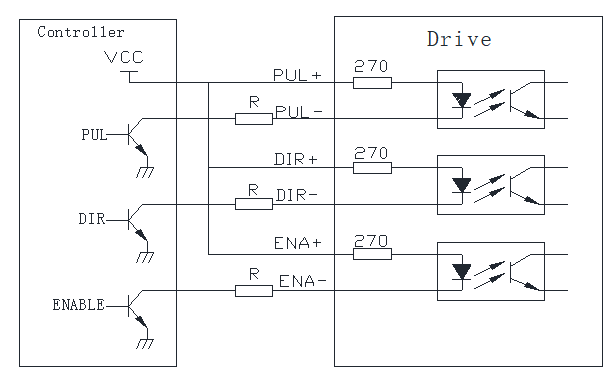

PUL+(+5V) | 脉冲控制信号:脉冲上升沿有效;PUL-高电平时4~5V,低电平时0~0.5V。为了可靠响应脉冲信号,脉冲宽度应大于2.5如采用+12V或+24V时需串电阻。 Pulse control signal: pulse rising edge is valid; PUL-high level is 4~5V, low level is 0~0.5V. In order to respond reliably to pulse signals, the pulse width should be greater than 2.5. If +12V or +24V is used, string resistance is required. |

PUL-(PUL) | |

DIR+(+5V) | 方向信号:高/低电平信号,为保证电机可靠换向,方向信号应先于脉冲信号至少 5μs建立。电机的初始运行方向与电机的接线有关,互换任一相绕组(如A+、A-交换)可以改变电机初始运行的方向,DIR-高电平时4~5V,低电平时0~0.5V。 Direction signal: High/low level signal. To ensure reliable commutation of the motor, the direction signal should be established before the pulse signal is at least 5μs. The initial running direction of the motor is related to the wiring of the motor. Interchanging any phase winding (such as A+, A-exchange) can change the direction of the initial running of the motor, DIR-high level 4~5V, low level 0~0.5V. |

DIR-(DIR) | |

ENA+(+5V) | 使能信号:此输入信号用于使能或禁止。ENA+ 接+5V,ENA-接低电平(或内部光耦导通)时,驱动器将切断电机各相的电流使电机处于自由状态,此时步进脉冲不被响应。当不需用此功能时,使能信号端悬空即可。 Enable signal: This input signal is used to enable or disable. When ENA+ is connected to +5V and ENA- is connected to low level (or internal optocoupler is on), the driver will cut off the current of each phase of the motor to make the motor free, and the step pulse will not be responded. When this function is not needed, the enable signal is left floating. |

ENA-(ENA) |

引脚(Pin) | 功能说明(Function description) |

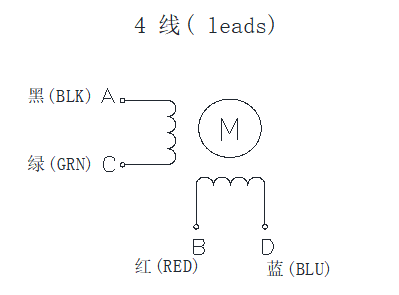

A+ | 两相步进电机A+相(Motor Phase A+) |

A- | 两相步进电机A-相(Motor Phase A-) |

B+ | 两相步进电机B+相(Motor Phase B+ |

B- | 两相步进电机B-相(Motor Phase B-) |

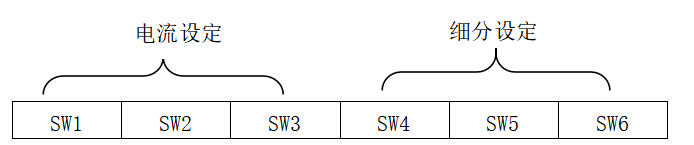

态电流设定(Dynamic current setting)

输出峰值电流 Peak Current | 输出有效值电流 RMS Current | SW1 | SW2 |

SW3 |

Default 1.5A【PK】 | oN | oN | oN | |

2.1A | 1.5A | oFF | oN | oN |

2.7A | 1.9A | oN | oFF | oN |

3.2A | 2.3A | oFF | oFF | oN |

3.8A | 2.7A | oN | oN | oFF |

4.3A | 3.1A | oFF | oN | oFF |

4.9A | 3.5A | oN | oFF | oFF |

5.6A | 4.0A | oFF | oFF | OFF |

步数/转(1.8°电机) Steps/rev. (for 1.8°motor) | SW4 | SW5 | SW6 |

Default(400) | ON | ON | ON |

800 | OFF | ON | ON |

1600 | ON | OFF | ON |

3200 | OFF | OFF | ON |

4000 | ON | ON | OFF |

5000 | OFF | ON | OFF |

6400 | ON | OFF | OFF |

12800 | OFF | OFF | OFF |

该款电机可以根据客户需求定制。

The motor can be designed &manufactured with customized request.

注意:VCC值为5V时,R短接;

VCC值为12V时,R为1K,大于1/8W电阻;

VCC值为24V时,R为2K,大于1/8W电阻;

Copyright 2023 Copyright Changzhou Fulling Motor Co., Ltd

【 Disclaimers 】